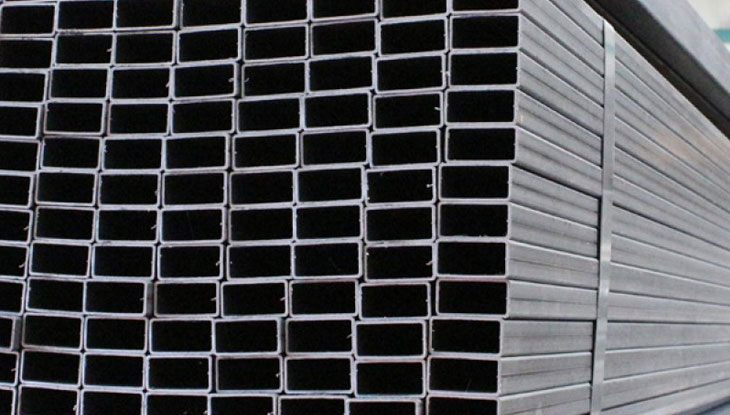

Cold Rolled Profiles

Cold rolled sections are produced by forming round wire rod, which can have a maximum diameter of 1”, by a continuous rolling process at ambient temperature. Cold rolling is a very efficient manufacturing process which has been developed mainly for small sections. Compared to hot rolling, cold rolling offers some considerable advantages. Excellent surface finish, tight tolerances and the possibility to produce very small production lots are the most obvious. Cold rolling provides the ability to change the mechanical properties of the material and produces certain useful combinations of hardness, strength, stiffness and ductility. This is completed by selective annealing. Montanstahl has placed its strategic cold rolling focus on high alloyed and stainless steel. The sections can be supplied either as bars in fixed lengths up to 19’ –0/+8” or can be recoiled. The bundles can be cut to length with a tolerance of +/- 1/2”. Typical production quantities start at 1 ton. Cold rolled stainless steel sections are used for watch components, food processing, textile, pulp and paper industry as well as petrochemical and nautical components.